DRY-FLO separators are designed for horizontal or vertical installations.

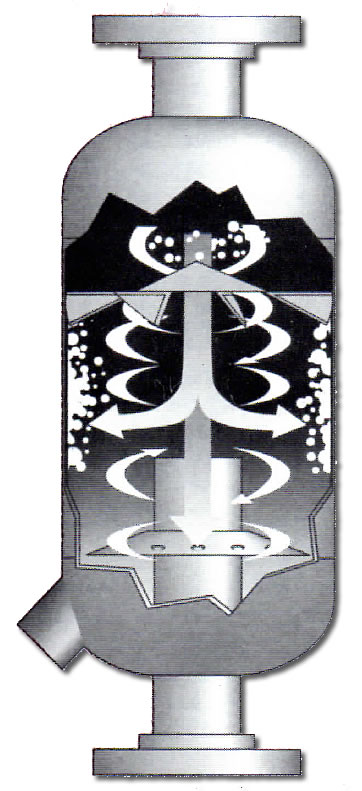

The stainless steel separating tuyere diffuser causes the steam to enter a controlled centrifugal flow. Due to the centrifugal motion, entrained liquids and solids are directed to the outer walls of the separator. Re-entrainment breaker plates create a quiet inert zone to prevent liquids and solids from re-entering the flow stream once separation has taken place.

With correct sizing and proper drainage these separators are designed to eliminate 99% of all entrained liquids and solids that are 10 microns and larger in size.

All DRY-FLO separators are manufactured in accordance with ASME Code Section VIII Div 1. All models are available in carbon steel and stainless grades. Most material types are available upon request.

DRY-FLO Applications:

- Keep steam equipment clean and eliminates fouling of regulators, burgines, valves, etc.

- Removes moisture form compressed air lines in plant service.

- Removes line scale, liquids and other contaminants from process gas and air lines

- Removes condensate and oil from compressed gasses in intercooler and aftercooler service at compessor stations.